Application moteur « temps zéro »

Type d’intervention

Mise en serviceLieu

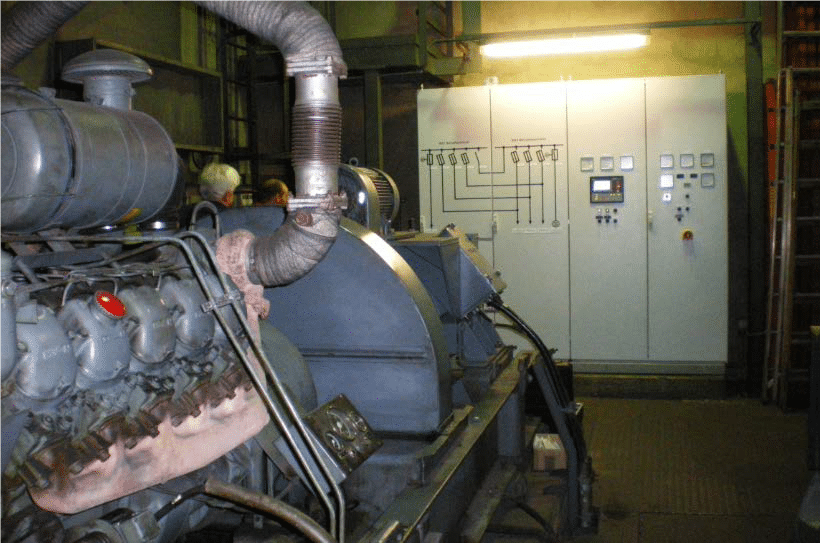

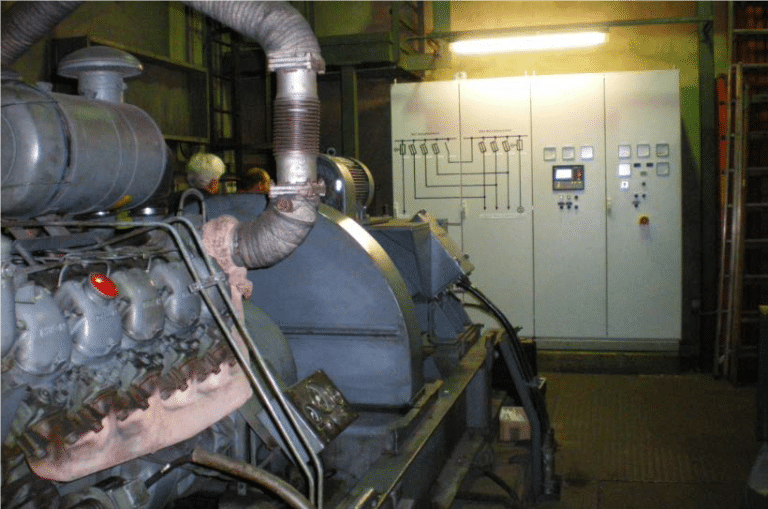

AllemagneDescription de l’application

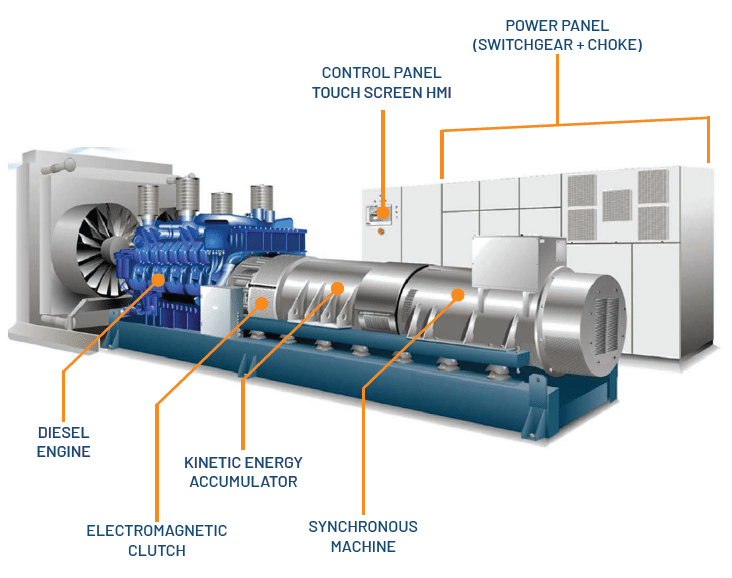

Les générateurs équipés de moteurs dit « temps zéro » sont des groupes électrogènes sur lesquels est embrayé un volant d’inertie de plusieurs tonnes entre l’alternateur et le moteur. Le but de ce type de montage est de permettre une rotation permanente de l’alternateur entrainée par le volant d’inertie sans utilisation du moteur, et donc sans usure mécanique ni utilisation de combustible, tout en ayant l’assurance d’une alimentation de secours effective en quelques dixièmes de secondes.

L’application présentée ci-dessous est celle d’une installation de secours sur un site pétrolier Allemand dédié au raffinage et à la transformation du pétrole. Les contraintes de ce type d’application entrainent une adaptation complète des séquences de démarrage et d’arrêt, ainsi que la gestion du couplage et de l’embrayage, CRE TECHNOLOGY a donc proposer une adaptation spécifique du GENSYS 2.0 en couplage réseau pour répondre à la demande du client.

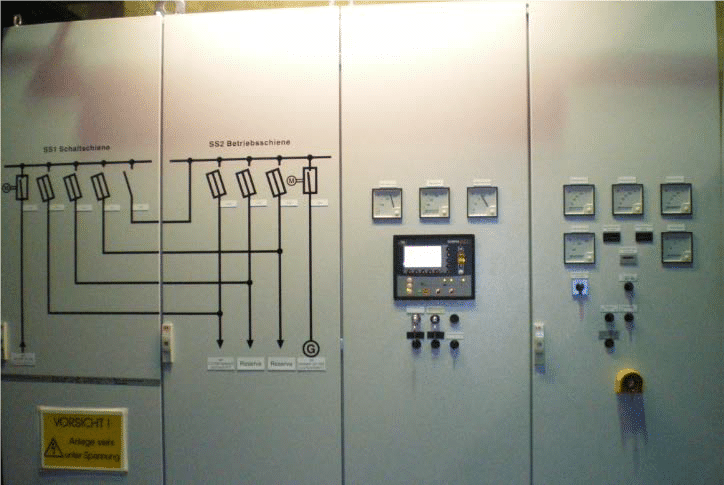

La solution technique

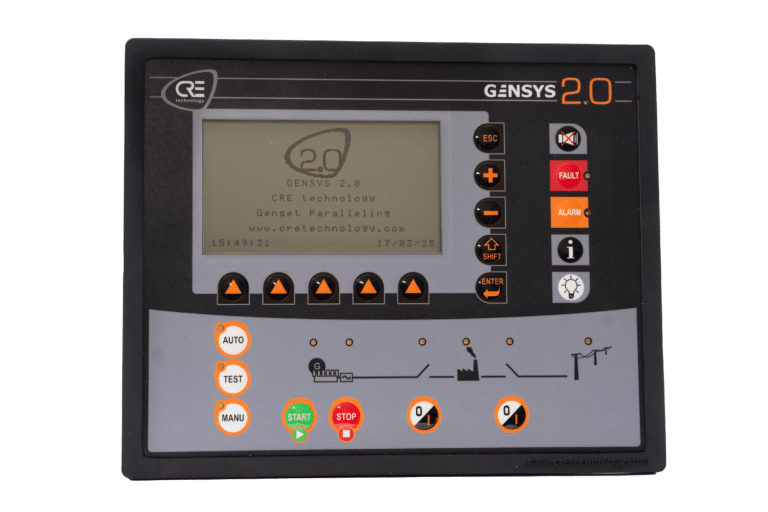

Le GENSYS 2.0 utilise toute ses capacités en termes d’automatisme interne afin de gérer la séquence complexe de lancement et de couplage du générateur ; contrairement aux générateurs traditionnels, le temps 0 est démarré une première fois selon une séquence très longue pour lancer le volant d’inertie, une fois le volant à vitesse nominale le moteur est débrayé et c’est un moteur électrique qui prendra le relais de maintien en vitesse de la roue, à ce moment l’excitation est désactivé sur l’alternateur et l’installation prête en cas de manque secteur. Lorsque le manque secteur est détecté, le rôle du GENSYS 2.0 est d’exciter l’alternateur dans un délai très court et de basculer la charge sur l’alternateur afin de permettre le secours électrique du site pendant que le moteur est lancé et embrayé.

Une fois que le moteur est alimenté en fuel et embrayé sur l’alternateur, le générateur re¬prend un fonctionnement classique. Au-delà de la séquence définie pour la reprise sur perte secteur, le GENSYS 2.0 intègre égale¬ment un mode de test et un mode manuel spécifique à cette installation.

Produits installés

- GENSYS 2.0

Schéma de l’application

Les produits associés

GENSYS 2.0

Le GENSYS 2.0 est un contrôleur « tout-en-un » complet et compact incluant la gestion moteur, la synchronisation, la puissance active et réactive, le contrôle jusqu’à 32 générateurs ou d’un seul générateur en parallèle avec le réseau

Ajouter au devis